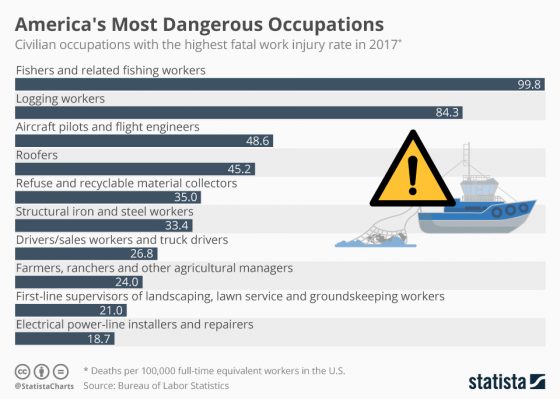

Construction is consistently ranked as one of the riskiest jobs in the United States. Fluid workforces, high-risk scenarios and a communication disconnect between home office and front-line workers all result in the very real possibility of serious injury or even death.

One of the major challenges in the construction industry is getting information and training to the front-line workers who face the most risk, but are often the least informed. Company emails and company-issued phones go as far as the foremen but do not always make it down to the crew themselves. Training is not always readily available or is more compliance-based than it is practical for the day’s work. This creates major risks for front-line workers, contractors, insurers and anyone involved with ensuring construction projects are safely and accurately completed. As a result, the construction industry is increasingly turning to new virtual and mobile technology tools. In an effort to improve its communication and training practices and provide critical information to its workers.

Visualizing High-Risk Scenarios

New, interactive modules are allowing safety teams to offer more effective and engaging job-site training in the form of videos, quizzes, virtual reality and 3D simulators. Exposure-based training platforms can also provide a “hands-on” experience, giving front-line workers the opportunity to encounter different situations while in a safe environment.

For example, a 3D simulation of a “hazard hunt” tests workers by having them identify all of the potential hazards on a building such as tilt, unsafe conditions and proximity to power lines and how to mitigate those risks. Fire safety prevention can be made into an immersive experience to help a worker identify the proper fire extinguisher based on the simulated fire, increasing the likelihood that they will make the right choice in the event of an emergency.

Simulations can also take tradesmen step-by-step through the process of working on specific tasks, allowing them to learn the process from start to finish and monitoring for the most common risk exposures. To become a signalman when working with cranes, the current process is to watch videos and memorize the hand motions. With simulators, workers can now be put into specific scenarios and learn how to proceed in the safest way and without endangering the person or equipment. Ultimately, new exposure-based training helps workers overcome any natural inclinations that put them in harm’s way and increases their awareness of all the risks of a specific task or job site.

Facilitating Effective Communication

Construction workers may be on a site for three months, or they might work on a job for one day. In both cases, contractors take on the same level of risk when it comes to ensuring each employee is appropriately trained. And with a workforce that is constantly in motion, construction managers face the challenge of tracking who has been trained on what. Paper filing systems and limited access to the training records while onsite can lead to oversights when it comes to identifying improperly trained workers.

Virtual training allows contractors to more easily track exactly who is trained on what, and store the important documents in a digital archive. By keeping critical information readily available digitally, onsite managers can more quickly confirm and step in if someone is not properly trained and manage overall communication for the duration of the project even as the job site’s workforce changes.

Builders are also using digital communication platforms to address the communication disconnect between the home office and the front-line workforce, and in order to reduce the risk of miscommunication. These apps allow teams to send messages, emergency alerts and even just-in-time training videos that can highlight safety hazards specific to the job site to individuals or entire crews in an instant, helping to reduce unnecessary work stoppages and operational friction. They can also deliver micro-training refresher courses so that workers can better retain and implement the new knowledge and skills they have learned.

By deploying new types of digital training techniques, companies can improve communication and provide the front-line workforce with the right information to make safe decisions on a job site, reducing overall risk and most importantly, ensuring that their workers get home safely.